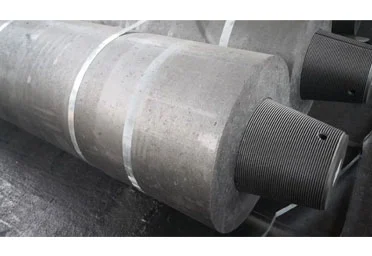

The graphite electrode from NORTH INDUSTRIES is mainly made of petroleum coke and needle coke as raw materials and coal tar pitch as binder. NORTH INDUSTRIES‘ graphite electrode is made by crushing, screening, kneading, molding, baking, impregnation, graphitization and machining. The graphite electrode is a conductor that releases electric energy in the arc furnace to heat and melt the burden.

Graphite electrodes play a pivotal role in steelmaking as they act as conductive elements in electric arc furnaces (EAFs). During the steelmaking process, these petroleum products transfer electrical current into the furnace, generating a high-temperature electric arc. This arc is essential for melting scrap steel, allowing for the refining and production of molten steel.

Graphite electrodes contribute to the efficiency and productivity of EAFs by providing a reliable means of heating and maintaining the necessary temperature for the steelmaking reactions, thereby playing a critical role in the overall production of quality steel.

Electric arc steelmaking furnace, using graphite electrodes to introduce current into the furnace for smelting.

Graphite electrode is used for mineral heating electric furnace, heating charge.

Graphite electrode can be processed into various graphite products such as crucible, mold, boat and heating body.

Graphite electrode is used for preparing resistance furnaces.

Graphite electrode production process begins with raw material preparation, primarily petroleum coke, which is crushed and mixed with binder materials. The mixture is then formed into electrodes via molding processes and baked to remove volatile components. Subsequently, electrodes undergo graphitization at extreme temperatures, transforming the carbon structure into graphite.

NORTH INDUSTRIES' Graphite electrode machining ensures precise dimensions and surface finish. Quality control measures, including non-destructive testing, guarantee adherence to standards. Finally, graphite electrodes are coated for protection and packaged for shipment. This intricate process ensures the production of high-quality electrodes crucial for electric arc furnaces in steelmaking, vital for modern industrial operations.