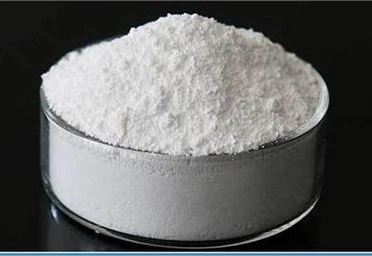

NORTH INDUSTRIES Magnesia material(MgO) is a white powder that is odorless, tasteless, and non-toxic at room temperature. Its melting point is 2852℃, the boiling point is 3600℃, its density is 3.58 g cm-3, and the MgO magnesium is insoluble in water and ethanol.

Magnesium oxide is extracted from magnesia and "stripped" at high temperature to form magnesium oxide powder, usually used as refractory material. Magnesia carbon refractory is a widely used refractory material in steelmaking.

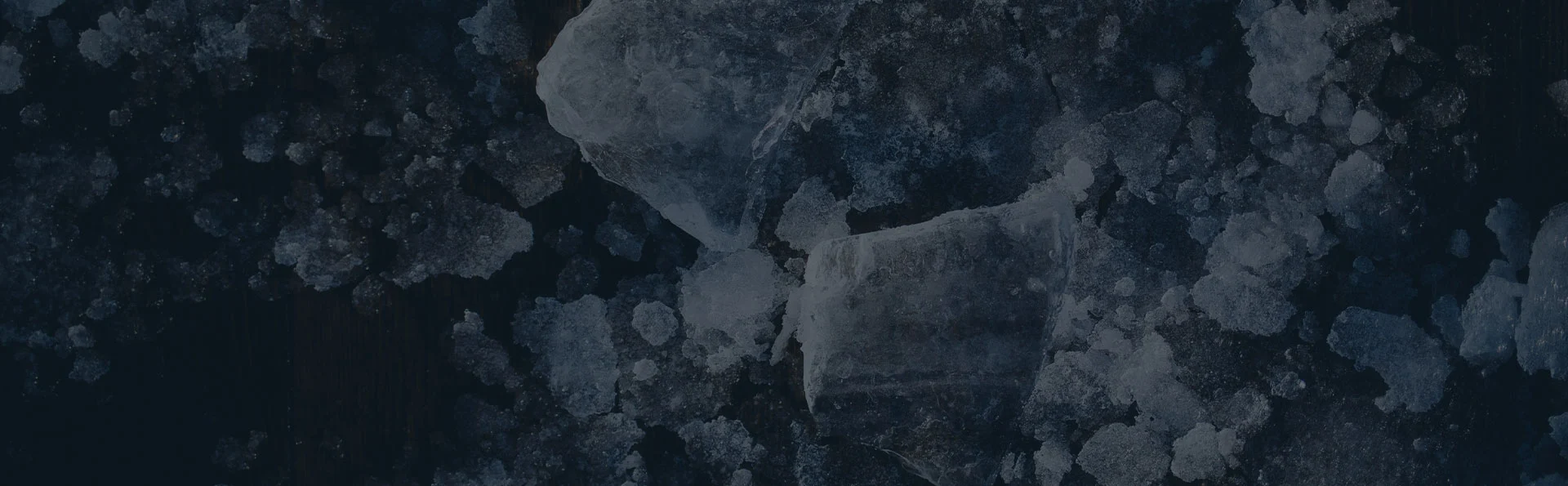

Magnesite is a magnesium carbonate mineral, the chemical formula: MgCO3, the main source of magnesium, is one species of China's non-metallic minerals.

Magnesite is mainly produced in Zimbabwe, Brazil, Australia, and China. China is rich in magnesite and dolomite resources, and is the world-famous "magnesium country", its production is distributed in Liaoning, Shandong, Xizang, Xinjiang, Gansu, Hebei and other provinces and regions, of which Liaoning has the largest reserves of resources.

Magnesite is widely used in metallurgy, building materials, ceramics, chemical industry, and other fields. For example, in the metallurgical industry, magnesite can be used to make steel, magnesium, aluminum, and other metals. In the building materials industry, magnesite can be used to make high-strength lightweight concrete, but also can be used as wall panels, porcelain tiles, fireproof materials, and so on. In addition, magnesite can also be used to make a variety of refractory materials, such as castables, bricks, and blocks.

As a professional magnesium oxide manufacturer and supplier, we produce dead burned magnesia oxide for a wide range of applications, including:

Used in the chemical industry to manufacture magnesium metal and magnesium chemicals;

In the metallurgical industry, it is mainly used in the lining of steel furnaces as refractory materials, and is also used in the production of refractory materials such as calcium magnesia brick, magnesia carbon brick, and magnesia aluminum brick in the construction industry;

Used in medicine as an antacid and laxative agent;

In food processing, it can be used as a decolorizing agent for sugar refining.

The largest use in agriculture is as fertilizer and feed for livestock

Production of magnesium oxide by traditional method

The traditional method to produce magnesium oxide is mainly to roast light-burned magnesia, and then prepare it by water extraction, filtration, drying and other steps. The process principle is simple, but the yield is low, and there are many process links and the cost is high.

Production of magnesium oxide by electrolysis in electrolysis, magnesium and oxygen can be separated by electrolysis in hot molten potassium carbonate, so that they can be separated from minerals to form magnesium oxide. This method has the advantages of high yield and low cost, but it needs to be carried out under high temperature and high pressure.

Chemical production of magnesium oxide Chemical production of magnesium oxide is mainly treated by chlor-alkali method or acid method. For example, magnesium oxide can be prepared by reacting sodium hydroxide or ammonium hydroxide in magnesite. Although high-purity magnesium oxide can be produced, there is a problem of toxic substances.

Production of magnesium oxide by photo-oxidation method By photo-oxidation method, magnesite is placed in an oxygen-containing environment for environmental photocatalytic reaction to deoxidize it and form magnesium oxide. The advantage of this method is that it does not need high temperature and high pressure, and the process is simple, but its output still needs to be improved.

In a word, the production processes of magnesium oxide include traditional method, electrolytic method, chemical method and photooxidation method. According to different process principles and production conditions, the corresponding process mode is selected for production.

Magnesium oxide has a wide range of applications, including:

Used in the chemical industry to manufacture magnesium metal and magnesium chemicals; In the metallurgical industry, it is mainly used in the lining of steel furnaces as refractory materials, and is also used in the production of refractory materials such as calcium magnesia brick, magnesia carbon brick and magnesia aluminum brick in the construction industry; Used in medicine as antacid and laxative agent; In food processing, it can be used as a decolorizing agent for sugar refining. The largest use in agriculture is as fertilizer and feed for livestock.