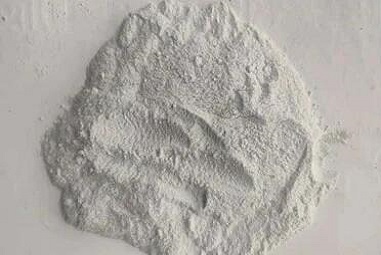

Petroleum coke, or petcoke, is a byproduct of the oil refining process. It is a highly carbonaceous solid material that is used as a fuel in various industries, including the cement industry. Petcoke production involves the thermal decomposition of heavy atmospheric residue in coker units, resulting in the formation of solid coke particles.

The cement industry is one of the largest consumers of petcoke due to its high calorific value and low ash content. Pet coke burns hotter and cleaner than coal, resulting in lower emissions of sulfur dioxide and nitrogen oxides. This makes it a cost-effective and environmentally friendly fuel option for cement manufacturers, helping them meet regulatory emissions standards.

Despite its benefits, the use of pet coke in the cement industry has raised concerns about its impact on air quality and public health. The combustion of petcoke releases particulate matter and greenhouse gases into the atmosphere, contributing to air pollution and climate change. In response, regulatory agencies have implemented stricter emission limits and monitoring requirements for industries using petcoke as a fuel.

In conclusion, pet coke plays a vital role in the cement industry as a cost-effective and efficient fuel source. However, it is important for petcoke production and use to be managed responsibly to minimize environmental impacts. By adhering to regulatory requirements and investing in clean technologies, cement manufacturers can continue to benefit from pet coke while mitigating its potential negative effects on the environment.